Fluid power systems play a crucial role in various industries, enabling the efficient transfer of power through the use of fluids. Among the key components of these systems are directional control valves, which are responsible for controlling the flow and direction of fluids. Directional control valve manufacturers are instrumental in optimizing fluid power systems, ensuring their reliable and efficient operation. In this article, we will explore the significant role of directional control valve manufacturers in optimizing fluid power systems.

Understanding Fluid Power Systems

Definition of Fluid Power Systems

Fluid power systems utilize fluids, such as hydraulic oil or pneumatic air, to transmit power and control mechanisms in various industrial applications. These systems provide high force and motion control capabilities, making them ideal for heavy-duty operations.

Components of Fluid Power Systems

Fluid power systems consist of several key components, including pumps, actuators, reservoirs, filters, and valves. Among these components, directional control valves hold significant importance as they regulate the flow and direction of fluid within the system.

The Importance of Directional Control Valves

Definition and Function

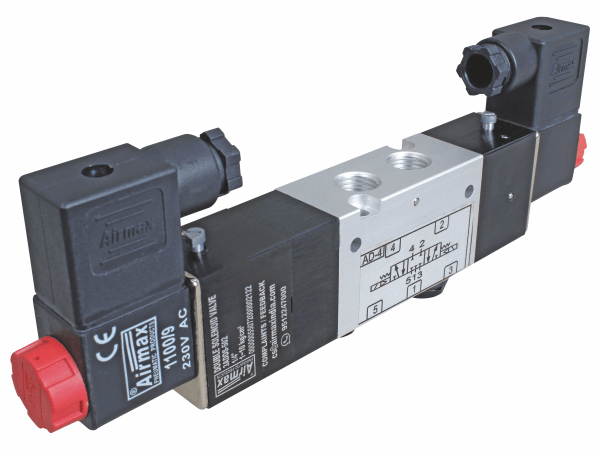

Directional control valves are devices that determine the flow path of fluids in a fluid power system. They enable operators to control the direction of fluid flow, start or stop fluid flow, and redirect fluid from one channel to another. These valves are essential for the efficient and precise operation of fluid power systems.

Types of Directional Control Valves

Directional control valves come in various types, such as spool valves, poppet valves, and rotary valves. Each type offers unique advantages and is suitable for specific applications. Spool valves, for example, are commonly used for precise control and modulation of fluid flow, while poppet valves are known for their quick response and high flow rates.

The Role of Directional Control Valve Manufacturers

Design and Engineering Expertise

Directional control valve manufacturers play a vital role in optimizing fluid power systems through their design and engineering expertise. They employ skilled professionals who understand the intricacies of fluid dynamics and can develop valves that meet specific application requirements. By considering factors such as flow rates, pressure ratings, and compatibility with different fluids, manufacturers ensure that their valves contribute to the overall efficiency and performance of the system.

Customization and Adaptability

Fluid power systems vary greatly in their applications and operating conditions. Directional control valve manufacturers recognize this diversity and offer customization options to meet specific needs. They can tailor valves to fit unique system requirements, including size constraints, environmental conditions, and performance expectations. This customization and adaptability enable the optimization of fluid power systems for maximum efficiency and effectiveness.

Quality Assurance and Compliance

Reliability and safety are paramount in fluid power systems. Directional control valve manufacturers adhere to stringent quality standards and regulations to ensure that their products meet industry requirements. Through rigorous testing and quality control measures, manufacturers verify the performance, durability, and safety of their valves. By using valves from reputable manufacturers, system designers and operators can have confidence in the longevity and reliability of their fluid power systems.

Research and Development

Directional control valve manufacturers invest in research and development to stay at the forefront of technology and innovation. They continuously explore new materials, design concepts, and manufacturing processes to improve the performance and efficiency of their valves. By keeping up with industry advancements, manufacturers can offer cutting-edge solutions that optimize fluid power systems. These ongoing research and development efforts contribute to the advancement of fluid power technology as a whole.

Benefits of Optimal Directional Control Valves

Enhanced Performance and Efficiency

Optimal directional control valves have a direct impact on the performance and efficiency of fluid power systems. By precisely controlling the flow of fluid, these valves minimize energy losses, reduce pressure drops, and ensure smooth operation. They allow for accurate positioning and control of actuators, resulting in improved productivity, reduced cycle times, and increased overall system efficiency.

Reduced Energy Consumption

Efficiency is a critical factor in any industrial system, including fluid power systems. Directional control valves optimized for minimal energy consumption can significantly reduce operating costs. By minimizing pressure losses, leakage, and unnecessary fluid flow, these valves help conserve energy and promote sustainability in industrial operations.

Increased System Reliability

Reliability is crucial in fluid power systems, as any failure or malfunction can lead to costly downtime and potential safety hazards. Optimal directional control valves, manufactured with high-quality materials and precision engineering, offer enhanced reliability and durability. They can withstand harsh operating conditions, resist wear and corrosion, and maintain consistent performance over an extended lifespan.

Industry Applications of Fluid Power Systems

Fluid power systems find application in a wide range of industries due to their versatility and power transmission capabilities.

Manufacturing and Automation

In manufacturing and automation, fluid power systems are commonly used for machine control, material handling, and assembly operations. These systems provide the force and motion necessary for precise positioning, lifting heavy loads, and operating robotic machinery. Directional control valves ensure accurate control of actuators, enabling smooth and efficient operation in manufacturing processes.

Construction and Heavy Machinery

Fluid power systems play a vital role in construction and heavy machinery applications. Hydraulic systems, in particular, are widely used for lifting and moving heavy objects, operating construction equipment, and providing stability and control in various tasks. Directional control valves enable the precise control of hydraulic cylinders and motors, allowing for the safe and efficient operation of construction machinery.

Aerospace and Defense

The aerospace and defense industries rely on fluid power systems for a range of applications, including aircraft landing gear, flight control systems, and weapon systems. These systems require precise control and reliability in extreme conditions. Directional control valves designed and manufactured to meet stringent aerospace and defense standards ensure the optimal performance and safety of fluid power systems in these critical applications.

Choosing the Right Directional Control Valve Manufacturer

Selecting the appropriate directional control valve manufacturer is crucial for optimizing fluid power systems. Consider the following factors when making your decision:

Evaluating Experience and Expertise

Look for manufacturers with extensive experience in designing and manufacturing directional control valves. A company with a proven track record and expertise in fluid power systems will have the knowledge and capability to provide reliable and efficient solutions.

Assessing Product Range and Customization Options

Consider the manufacturer’s product range and their ability to customize valves to suit your specific requirements. A wide selection of valve types, sizes, and configurations ensures that you can find the most suitable solution for your fluid power system.

Verifying Quality Standards and Certifications

Ensure that the manufacturer adheres to recognized quality standards and holds relevant certifications. This guarantees that their valves meet industry requirements for performance, durability, and safety.

Considering After-Sales Support

Evaluate the manufacturer’s after-sales support, including warranty, technical assistance, and availability of spare parts. Timely support and service are essential for the ongoing performance and maintenance of your fluid power system.

Conclusion

Directional control valve manufacturers play a vital role in optimizing fluid power systems. Through their design expertise, customization options, quality assurance, and commitment to research and development, they contribute to the performance, efficiency, and reliability of these systems. By choosing the right manufacturer and utilizing optimal directional control valves, industries can maximize the benefits of fluid power technology and achieve efficient and sustainable operations.